Factory Five Racing 818 Coupe

In this particular project, the customer had purchased a half completed kit to finish, but was uncertain of the previous owner’s attention to quality based on a few issues. At the time of discussion, our customer reported concerns about certain fitment issues, the re-install of ABS and cruise control, a required HVAC unit, exhaust and rough running.

After we understood the concerns, we removed the bodywork and began to inspect all previous work completed. We found issues immediately. None of the suspension nuts were properly tightened, control arm lengths were mismatched, the exhaust header was dented from bottoming out, shift linkages barely worked, and etc. Of the most concerning was the wholly inadequate and dangerous wiring work done by the previous owner.

With our inspection complete, we went to work remedying the issues we found. For the ABS and cruise control, we sourced the required modules, sensors and cables from a defunct Subaru and proceeded to reconnect them into the vehicle electronics. As for the ABS, additional cost was incurred as the brake line previously installed was a single line with multiple unions. Not only did this not work as we need each brake caliper to have it’s own line from the ABS module, all the unions created the multiple points of failure. Not acceptable for such an important system.

Due to space constraints and not wanting to add too much weight, we opted for a very short run and simple exhaust system. Thankfully with some additional time and care around the exhaust outlets and the capped end being a cone rather than a flat plate, we have good sound control and very little drone from the system. Additionally, as far as we can tell, there is next to no back pressure at the current power the engine is producing despite the abrupt change in direction of exhaust flow at the outlets. We attribute this the the total area of the two outlets being greater than the area of the 4” exhaust, and the time we took to modify the pipes to “direct” airflow out.

By far, the biggest struggle with this project was the wiring. Due to the removal of “redundant” wires by the previous owner, we spent most of our time correcting his mistakes to get the engine to run correctly, and then the additional time to wire back in the ABS and cruise control.

A custom 1/2 stainless steel flange was cut out and a 5" to 4" reducer was worked to match the internal shape of the flange.

4 " exhaust bends were used to mate up to a 4" resonator from Vibrant performance which was hard mounted to the transaxle.

The exhaust tips are secured into the resonator through holes cut perpendicular to air flow. Internally, both pipes have a 45 degree cut with, left pipe being longer internally, and the mouth facing the incoming airflow.

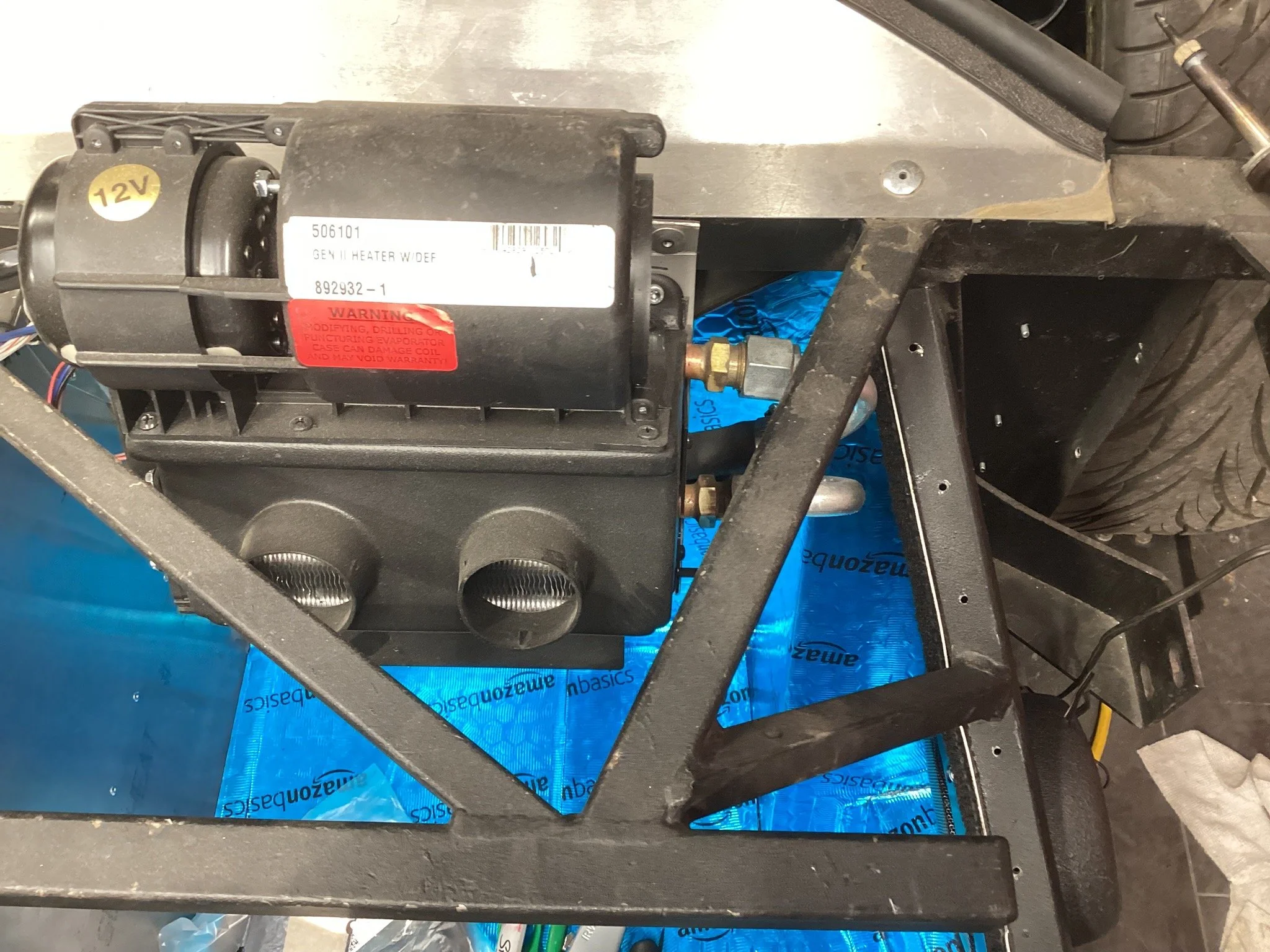

A very tight and peculiar space to fit an HVAC unit. The JIC fittings required some manual bending to accommodate the mounting position.

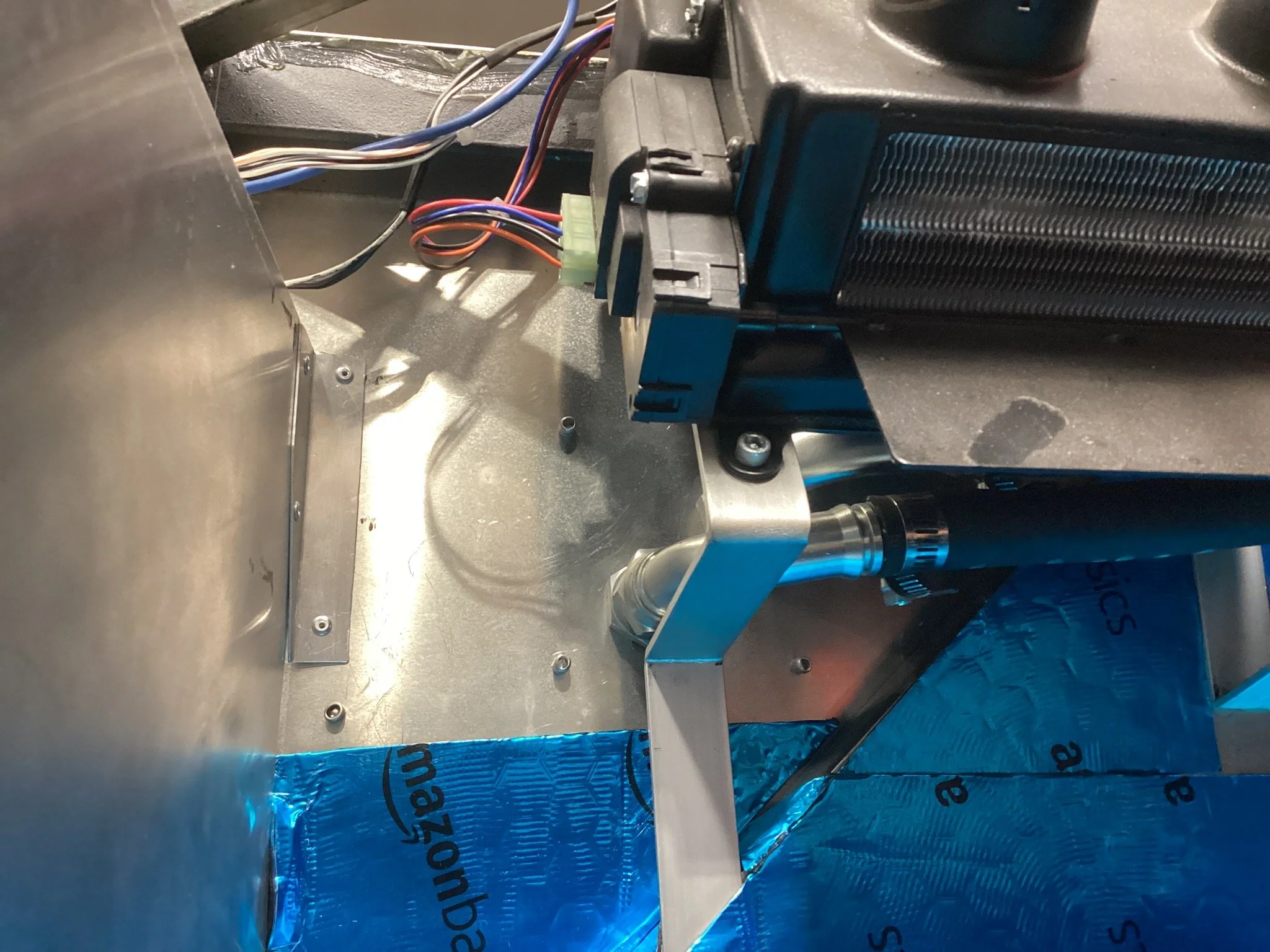

Custom mounting brackets for HVAC unit and interior view of bulkhead fittings for coolant lines

A reinforcement plate was installed on the bulkhead where the -10 stainless JIC fittings are secured beside the ABS module.

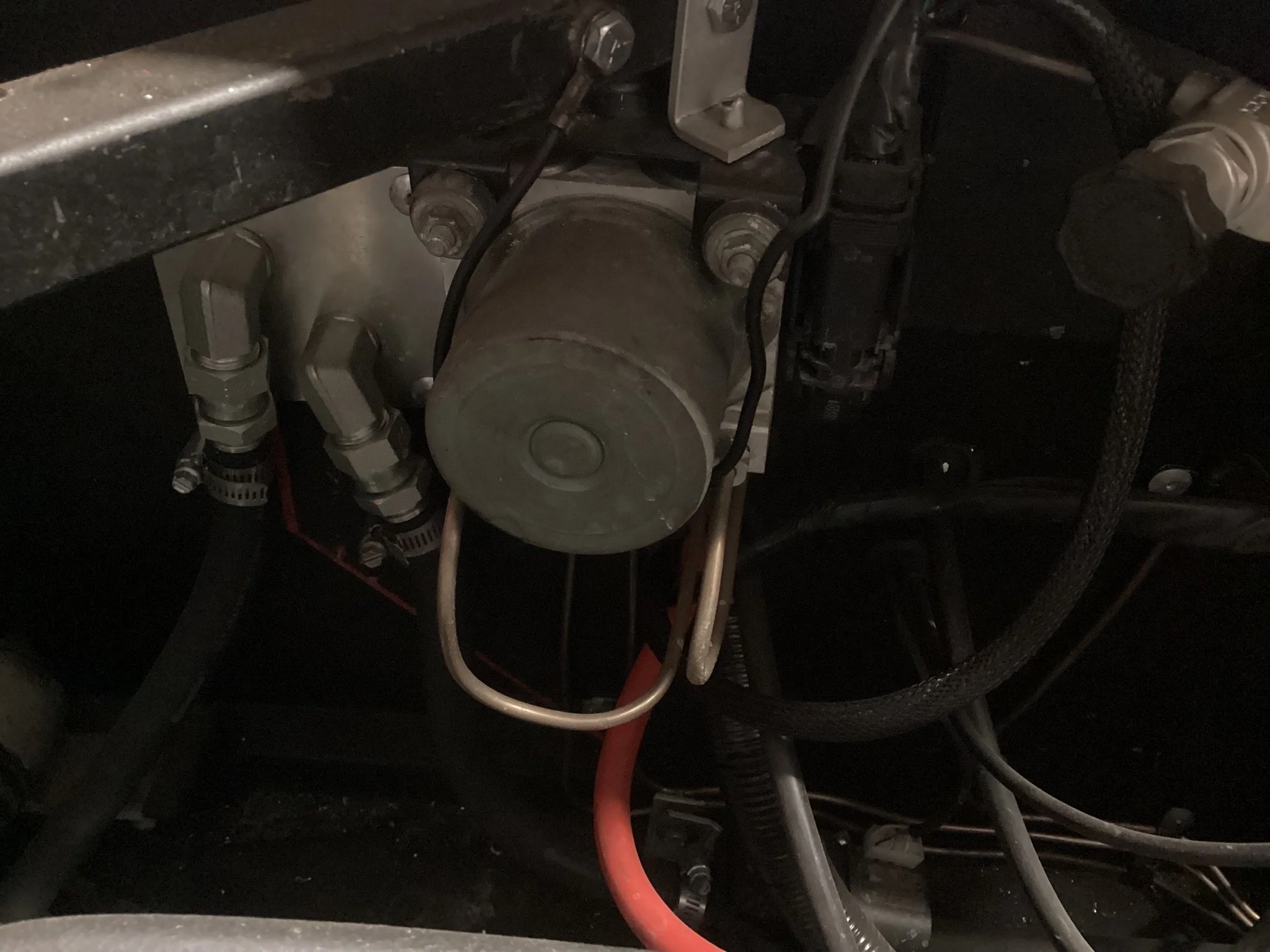

Brake Master Cylinder and Clutch Master Cylinder with new lines and fittings

Photo shows the following: - Taking measurements for ABS module mounting and coolant bulk head fittings for HVAC - One piece copper alloy lines for rear brakes from ABS and single line for clutch slave - Wiring harness repairs and re-integration of ABS module and cruise control module

Photo shows the following: - One piece copper alloy lines for rear brakes from ABS and single line for clutch slave - Wiring harness repairs and re-integration of ABS module and cruise control module

Wiring harness properly secured in transmission tunnel

ECU mounted with rubber isolators to firewall